Thinking vs. Efficiency 1

A confession. Despite Deming and others’ building some of the foundational thinking for lean, as a recovering “toolhead” engineer with a technical slant, I was a relative latecomer to the world of “systems thinking”. I put it in speech marks as I know it is a massive oversimplification, generalisation and open to debate. That, however, is a rabbit hole that I do not want to go down in this brief article. What I do want to do is to try to visualise some of my basic thinking with respect to the subject and try to articulate the impact it has had on my approach and viewpoints. I have already discussed this cathartic feeling a little in an earlier blog entitled “If you change the way you look at things – learning NOT to see and blinded by muda”. The question of how to show the relative impact of thinking vs efficiently is one which I want to tackle with the help of Donella Meadow’s 12 Leverage Points.

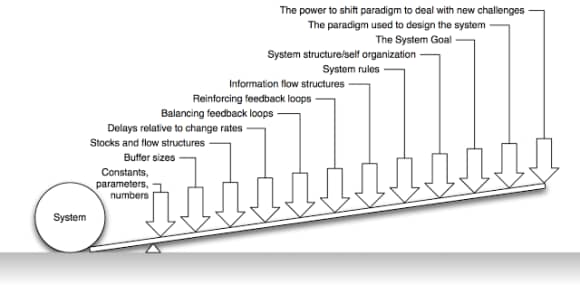

When first keen to learn more about how to view, define and describe a system and it’s behaviour I was recommended Donella Meadow’s 2008 book “Thinking in Systems: A Primer”. The book includes a section and summary detailing some of Meadow’s earlier papers regarding how to go about changing a system, “Leverage Points: Places to Intervene in a System”. This is often visualised with a fulcrum and a lever.

This diagram is a goto favourite of mine as it has much read across to models like Shingo, for example (we will cover this in a later blog). As a lean buff I don’t totally agree with some of the sequencing and positioning but overall it is a powerful and practical depiction. Exponential growth is in the news quite a lot, at present, and In a recent discussion about the relative potential impact of each intervention on the fulcrum it seemed to me that this should be incorporated in some way. I have had a go at modifying the simple diagram to do just that.

You Could Just be Going Faster in the Wrong Direction

There is a lot more to unpack about this as it is a huge assumption that the impact on the system can be exponentially greater the further to the right you go. It is a step on from Daniel Kim’s Systems Thinking “Iceberg” model covered in a previous blog. At least it is a starting point for a lively discussion. What is clear is that towards the left you are definitely in danger of going faster (or more efficiently) in the wrong direction and as Peter Drucker is quoted as saying “there is nothing so useless as doing efficiently that which should not be done at all”. Ever increasing levels of this “efficiency” can not only take you in the wrong direction it can strip out the capacity or flex that is needed for the system to be resilient. With the human elements, generally, on the right-hand side of the diagram it would seemingly backup the notion that changing thinking through innovation or advocacy (leadership) can be leveraged and result in large positive gains. It sits well with the hypothesis that the Toyota Production System has often been described by Toyota leadership and alumni as the Thinking system.