Thinking vs. Efficiency 2

A story of a beach ball, a “eureka” moment and lean success.

Lean’s Uncomfortable Reality

There is an uncomfortable reality when it comes to lean thinking and it’s widespread adoption. Like the Englishman shouting louder to be understood it doesn’t matter how many times or how loudly you say it’s just common sense, frustratingly, there are still many failed or lack-lustre attempts at lean adoption. In more recent times academics like Professor Bob Emiliani have written about this phenomenon and whilst there are a number of causal factors one definite contributing truth is that a number of key lean principles are counter-intuitive in their nature. Understanding this and designing a sympathetic lean strategy is essential. If individuals and organisations aren’t lucky enough to have experienced the counter-intuitive truths of lean such as flow, embrace the stop and mass learning, whatever strategy they choose will, most probably, end in efficiency not effectiveness. If the thinking hasn’t changed and the paradigm hasn’t shifted any lean endeavour will almost inevitably end in “fake” lean.

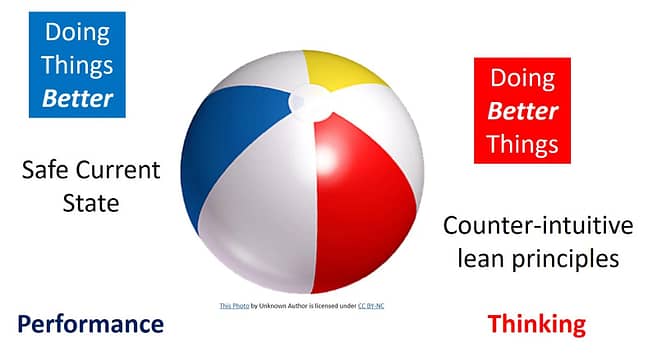

The Beach Ball Analogy – Seeing the Other Side of Things

A well-known facilitation technique is the beach ball analogy. It is used as a way to acknowledge that people may have a different view of the same thing and it doesn’t always mean that they are wrong, necesserily. It goes like this; imagine two people are looking at the same beachball. It has three white segments and three coloured segments; but each person can only see three segments on their side. So if you look from the left hand side you think the beach ball is only white and blue; and if you look from the right hand side it looks white, yellow and red. They’re both right but, they’re both different. They are both looking at exactly the same item or situation but seeing things completely differently. In our case the blue side is the side of the safe paradigm and efficiency and the opposite side is a new lean paradigm and effectiveness. One trouble with a counter-intuitive truth is explained by Robert “Doc” Hall in his 2001 AME article “The Counterintuitive Principles of the Toyota Production System” when he says “The (TPS) principles reinforce each other in non-linear fashion, so they are best learned experientially. A Toyota sensei seldom talks about them until after people have experienced TPS techniques and “peopleware” practices.The underlying philosophies clarify by first learning to”live the system,” then thinking deeply about it.” This normative experience is critical to being able to understand.

“Getting” Counter-intuitive Principles

Have you ever had big “aha” moment that was a real “light-bulb” revelation? This often happens when your mental model changes and a counter-intuitive truth becomes a reality to you. It is as if all the jigsaw pieces now fit together and you can see the picture with unbelievable clarity. What unlocks this is the experience of living in a system that you previously couldn’t or wouldn’t logically believe could work. Before that moment your mind just wouldn’t let you see. With a counter-intuitive no matter how many books you read or how much theory you discuss you will not be able to replicate that change of mental model. No matter which side of the beach ball you view it will always look to be white and blue. Even if you spin it fast or try and creep up on it! To succeed at deploying TPS enough leaders and managers must change their mental models. As Robert “Doc” Hall outlines and lists in his 2001 AME article there are many TPS fundamental principles that are completely at odds with the traditional intuitive management thinking. When leaders, consultants and practitioners decide to pick and choose the lean tools to use they often do it from the comfortable, safe side of the beach ball because they haven’t experienced the whole system working and don’t fully understand. This results in a patchy, sporadic deployment. Thinking genuinely has to change through experiential learning to be useful and useable.

The Key to Success is Doing Better Things

As a Japanese industrialist and the founder of Panasonic, Konosuke Matsushita was at the forefront of the rise of post-war Japanese industry. From the 1970’s onwards he was often interviewed, and the huge Matsushita corporation often studied and compared to it’s Western competitors. In their 1981 book “The Art of Japanese Management; Applications for American Executives” Richard Pascale and Anthony Athos detail a 1979 visit to Japan by a group of western dignitaries during which Konosuke Matsushita gave his now famous speech;

“We are going to win and the industrial west is going to lose out; there’s not much you can do about it because the reasons for failure are within yourselves. Your firms are built on the Taylor model. Even worse, so are your heads. With your bosses doing the thinking while workers wield the screwdrivers, you’re convinced deep down that it is the right way to run a business.”

“For you, the essence of management is getting ideas out of the heads of the bosses and into the heads of labour. We are beyond your mindset. Business, we know, is now so complex and difficult, the survival of firms so hazardous in an environment increasingly unpredictable, competitive and fraught with danger, that their continued existence depends on the day-to-day mobilisation of every ounce of intelligence.”

What Konosuke Matsushita and his contemporaries like Ohno understood was that the key to the success of their organisations wasn’t the tools, techniques, or processes as they were just designed to fix specific problems but instead it was the result of their management philosophies and principles. They had built interdependent systems on principles that support the correct behaviours throughout. With many of those principles being counter-intuitive it is a real beach ball barrier that many aspiring leaders, managers and change agents need to overcome and succeed.