Phase 1: Rapid Response and Initial Reset

Step 2: Survival, Kaizen and Speed 3

A Stark Contrast in Approach: An Anecdote

Picture the time, the middle to late 1990’s. The famous films around were “Titanic”, “The Big Lebowski” and “The Trueman Show”. The Spice Girls, Radiohead and The Verve were riding high in the UK charts and England was gearing up for hosting the European football championships. In lean terms it was 10 years since the first Bluebird was assembled at Nissan’s Sunderland plant and Womack and Jones’ “Lean Thinking” had only recently been published so, between 20 to 25 years ago. At the time I was working as a manager in a 1st tier automotive supplier and frequently invloved in quality, new product introduction and kaizen projects. Over the previous 5 to 6 years I had experienced interaction, training, audits and improvement projects with all the major motor manufacturers. The varying approaches taken by each of the different companies tells a tale. There was a real contrast between rigid, conservative, hierarchical bureaucracy and the nimble, agile and sure-footed. This tale starts with a genuine cost down offer.

Playing the Procurement Cost-Down Game

As a supplier, customer pressure for cost savings and cost down was constant. Most savvy suppliers were well versed in gaming the system using common tactics to bank their own savings. Squeezing out all the potential improvements in an area prior to the arrival of the customer’s supplier development team came on-site by running your own kaizen events was common. There was a very real contrast between the various customer’s methods, approaches and levels of collaboration. Some only focussed on their own products and lines and some looked to support the site overall. Often the biggest and most long-lasting savings came from value engineering (VE) design changes that gave both weight and matrial cost savings that were permanent. These were prized and valuable to the relationship.

Strangling Kaizen - A Hurdle too High

It was always best to focus VE efforts on high volume, universal components that could be used across multiple customer’s assemblies so we did. At the time our superb design team and toolmakers had developed a new tool that increased material yield whilst maintaining functional, structural and quality standards. The design was the same but the number that you could press from the coil increased substantially. The idea had originated from a natural work team kaizen forum. What happened next shows the power or not of local authority within organisations and structures.

When we offered this improvement as a cost saving to our customers there were two distinct answers. The first and majority answer was that it probably wouldn’t make the threshold saving required to trigger multiple drawing changes and the bureaucracy around such a request. This hurdle was in the tens of thousands of pounds. The second and minority response was one of reviewing the test data, making a call, signing and dating the modified drawing and taking a photocopy to take back to head office. This photocopy became part of an A3 that was used to describe the problem and the solution. This second response also authorised an immediate change to the new tool for their products to maximise the benefit for both ourselves and the customer. This is real kaizen in action, made possible by the flexibility of the organisation and authority channels. It meant an opportunity was immediately taken and an advantage made. This distributed responsibility and authority makes for a nimble and agile, kaizen response.

Kaizen and the Chief Engineer Structure

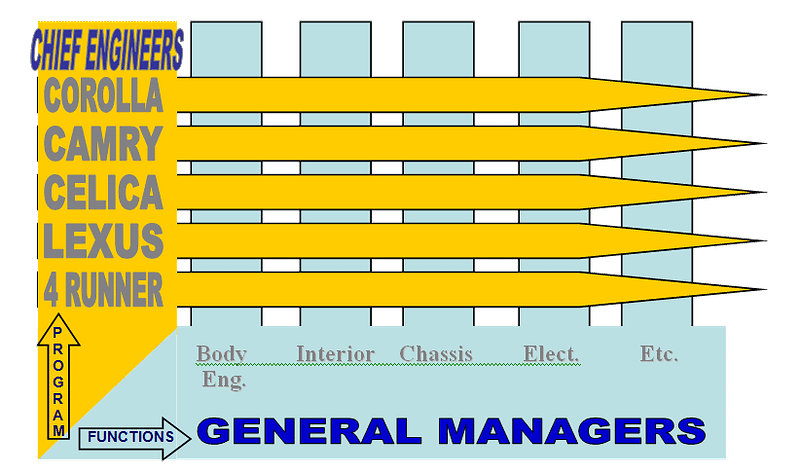

In John Shook’s excellent blog post from 2009 in praise of the Chief Engineer it is clear that the organisation and the role are fashioned to allow decisions to made in a robust yet rapid way with challenge and collaboration. He describes how everyone should able to show leadership when required. Likewise, in a 1998 Harvard Business Review article “Another Look at How Toyota Integrates Product Development”, co-authored by Jeffrey Liker, the issue of integration, close local leadership and standards feature heavily. Also, face-to-face communication combined with the use of written A3’s is explained. The organisation, structures, leadership, mentoring and methods of communication and collaboration via A3’s gives engineer’s the confidence to take responsibility and quickly make decisions.

Like the distributed and supportive natural work team structure in Toyota’s manufacturing facilities cherishes and drives local kaizen so does the fleet-footed chief engineer structure in engineering and new product development. Kaizen is at the very heart of the organisation, it’s principles and make-up. In these pandemic times organisations seriously need to decide whether they are going to develop kaizen-enabled organisations or whether they are going to miss out on the benefits of an engaged, distributed staff because they still have a rigid, hierarchical, un-trusting structure and style.

https://www.lean.org/leanpost/Posting.cfm?LeanPostId=1046

https://hbr.org/1998/07/another-look-at-how-toyota-integrates-product-development